Your How to make a fiberglass mold from an existing part images are ready in this website. How to make a fiberglass mold from an existing part are a topic that is being searched for and liked by netizens today. You can Download the How to make a fiberglass mold from an existing part files here. Get all royalty-free vectors.

If you’re searching for how to make a fiberglass mold from an existing part images information related to the how to make a fiberglass mold from an existing part topic, you have come to the ideal blog. Our site always provides you with hints for downloading the highest quality video and picture content, please kindly hunt and locate more enlightening video articles and graphics that fit your interests.

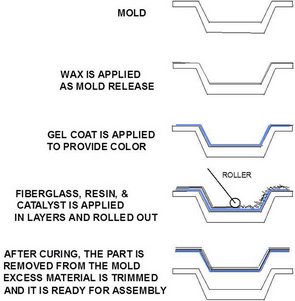

How To Make A Fiberglass Mold From An Existing Part. To make a fiberglass mold from an existing part we will normally mount the part on a backing board of some sort. Once the resin has cured you can pull the fiberglass mold from the foam pattern. Then you need to apply several layers of release wax to it. Clean the part well apply several layers of release wax and then apply fiberglass a few light plys at a time so it doesnt heat up and warp while drying.

Fiberglass Mold Making An Introduction To Plugs From fiberglasssupply.com

Fiberglass Mold Making An Introduction To Plugs From fiberglasssupply.com

In this video a motorcycle fender is repaired and given a textured surface. After that cures to a solid about 30 minutes lay in a layer of glass cloth and let it cure overnight. If playback doesnt begin shortly try restarting. How To Make A Fiberglass Mold For Making New Parts On Your Boat. Fiberglass starts off as a liquid. Click the Link For Composite Supplies Related to this Video.

If playback doesnt begin shortly try restarting.

Also Know how do you make a fiberglass spoiler. I sanded the underside of the part with 80. How To Make A Fiberglass Mold For Making New Parts On Your Boat. If the cloth or CSM has to be applied in sections make sure the sections overlap by at least one inch. After that cures to a solid about 30 minutes lay in a layer of glass cloth and let it cure overnight. Mix up a small batch of WEST SYSTEM 105 resin and 205 hardener for the gel coat layer and brush a thin even coat over the mold surface.

Source: boatinggeeks.com

Source: boatinggeeks.com

If the cloth or CSM has to be applied in sections make sure the sections overlap by at least one inch. Keep building it up until sufficient thickness has been made and then carefully peel it off the part. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. The first step in making a fiberglass mode out of an existing part is to clean that part very well. I sanded the underside of the part with 80.

Source: epoxyworks.com

Source: epoxyworks.com

How To Make A Fiberglass Mold For Making New Parts On Your Boat. Once the fiberglass part had cured for a day I removed it from the mold and trimmed around the perimeter of the part with a jigsaw. If playback doesnt begin shortly try restarting. A short lesson on building fiberglass molds and parts. Keep building it up until sufficient thickness has been made and then carefully peel it off the part.

Source: pinterest.com

Source: pinterest.com

A short lesson on building fiberglass molds and parts. If the cloth or CSM has to be applied in sections make sure the sections overlap by at least one inch. HttpbitlyMoldingFiberglassThis is Part 1 of 8This video is a Step By Step Guide To Molding. Mold release the hatch mold by the method in step 1 and apply a thin coat of epoxy to the inside of the mold. The first step in making a fiberglass mode out of an existing part is to clean that part very well.

Source: fiberglasssupply.com

Source: fiberglasssupply.com

Remove the pattern pull mold from container. Keep building it up until sufficient thickness has been made and then carefully peel it off the part. After that cures to a solid about 30 minutes lay in a layer of glass cloth and let it cure overnight. Do this while its still soft enough to work easily. Pull the rough hatch from the mold and trim to the finished shape with a Dremel tool and sand paper.

Source: fao.org

Source: fao.org

After that apply fiberglass one-ply or layer at a time so that they wont heat up and warp while drying. Do this while its still soft enough to work easily. After that apply fiberglass one-ply or layer at a time so that they wont heat up and warp while drying. Keep building it up until sufficient thickness has been made and then carefully peel it off the part. Turn mold upside down and sand until its flat.

Source: ecfibreglasssupplies.co.uk

Source: ecfibreglasssupplies.co.uk

Do this while its still soft enough to work easily. Similarly how do I make a fiberglass mold out of an existing part. How To Make A Fiberglass Mold For Making New Parts On Your Boat. Clean the part well apply several layers of release wax and then apply fiberglass a few light plys at a time so it doesnt heat up and warp while drying. Mold release the hatch mold by the method in step 1 and apply a thin coat of epoxy to the inside of the mold.

Source: boatinggeeks.com

Source: boatinggeeks.com

Click the Link For Composite Supplies Related to this Video. Do this while its still soft enough to work easily. Mold release the hatch mold by the method in step 1 and apply a thin coat of epoxy to the inside of the mold. The fiberglass strips have been covered with 105206410 and are ready to be faired. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold.

Source: boatinggeeks.com

Source: boatinggeeks.com

How To Make A Fiberglass Mold For Making New Parts On Your Boat. If playback doesnt begin shortly try restarting. Keep building it up until sufficient thickness has been made and then carefully peel it off the part. Also Know how do you make a fiberglass spoiler. Next place 50 grit sand paper on a flat surface.

Source: fiberglass-sales.com.au

Source: fiberglass-sales.com.au

Keep building it up until sufficient thickness has been made and then carefully peel it off the part. After that cures to a solid about 30 minutes lay in a layer of glass cloth and let it cure overnight. The first step in making a fiberglass mode out of an existing part is to clean that part very well. A short lesson on building fiberglass molds and parts. How To Make A Fiberglass Mold For Making New Parts On Your Boat.

Source: boatinggeeks.com

Source: boatinggeeks.com

Mix up a small batch of WEST SYSTEM 105 resin and 205 hardener for the gel coat layer and brush a thin even coat over the mold surface. Mold half the part. If playback doesnt begin shortly try restarting. Use the same WEST SYTEM epoxy that was used to build the mold to make your part. Click the Link For Composite Supplies Related to this Video.

Source: pinterest.com

Source: pinterest.com

Click the Link For Composite Supplies Related to this Video. Also Know how do you make a fiberglass spoiler. Keep building it up until sufficient thickness has been made and then carefully peel it off the part. How To Make A Fiberglass Mold For Making New Parts On Your Boat. If the cloth or CSM has to be applied in sections make sure the sections overlap by at least one inch.

Source: boatinggeeks.com

Source: boatinggeeks.com

After that cures to a solid about 30 minutes lay in a layer of glass cloth and let it cure overnight. Generally speaking we build all our molds with flanges assuming that at some point we will want to use them in a closed-molding or vacuum infusion process. Also how do I make a fiberglass mold out of an existing part. Fiberglass starts off as a liquid. Similarly how do I make a fiberglass mold out of an existing part.

Source: youtube.com

Source: youtube.com

Turn mold upside down and sand until its flat. Remove the pattern pull mold from container. The fiberglass strips have been covered with 105206410 and are ready to be faired. Let this layer of epoxy cure about 30 minutes. Generally speaking we build all our molds with flanges assuming that at some point we will want to use them in a closed-molding or vacuum infusion process.

Source: epoxyworks.com

Source: epoxyworks.com

How To Make A Fiberglass Mold For Making New Parts On Your Boat. This liquid is then extruded through tiny little holes which turn it into thin strands of threads. How To Make A Fiberglass Mold For Making New Parts On Your Boat. In this video a motorcycle fender is repaired and given a textured surface. A mold is then made and.

Source: epoxyworks.com

Source: epoxyworks.com

If playback doesnt begin shortly try restarting. Fiberglass starts off as a liquid. To mold a carbon fiber positive from the fiberglass mold you first apply a mold release wax to the fiberglass mold. Pull the rough hatch from the mold and trim to the finished shape with a Dremel tool and sand paper. The fiberglass strips have been covered with 105206410 and are ready to be faired.

Source: youtube.com

Source: youtube.com

To make a fiberglass mold from an existing part we will normally mount the part on a backing board of some sort. Let this layer of epoxy cure about 30 minutes. Also how do I make a fiberglass mold out of an existing part. A short lesson on building fiberglass molds and parts. How To Make A Fiberglass Mold For Making New Parts On Your Boat.

Source: fao.org

Source: fao.org

Keep building it up until sufficient thickness has been made and then carefully peel it off the part. A mold is then made and. Pull the rough hatch from the mold and trim to the finished shape with a Dremel tool and sand paper. Once the resin has cured you can pull the fiberglass mold from the foam pattern. Clean the part well apply several layers of release wax and then apply fiberglass a few light plys at a time so it doesnt heat up and warp while drying.

![]() Source: easycomposites.co.uk

Source: easycomposites.co.uk

Pull the rough hatch from the mold and trim to the finished shape with a Dremel tool and sand paper. Pull the rough hatch from the mold and trim to the finished shape with a Dremel tool and sand paper. Let this layer of epoxy cure about 30 minutes. Clean the part well apply several layers of release wax and then apply fiberglass a few light plys at a time so it doesnt heat up and warp while dryingKeep building it up until sufficient thickness has been made and then carefully peel it off the part. Mold release the hatch mold by the method in step 1 and apply a thin coat of epoxy to the inside of the mold.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to make a fiberglass mold from an existing part by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.